Cooling tower new or replacement

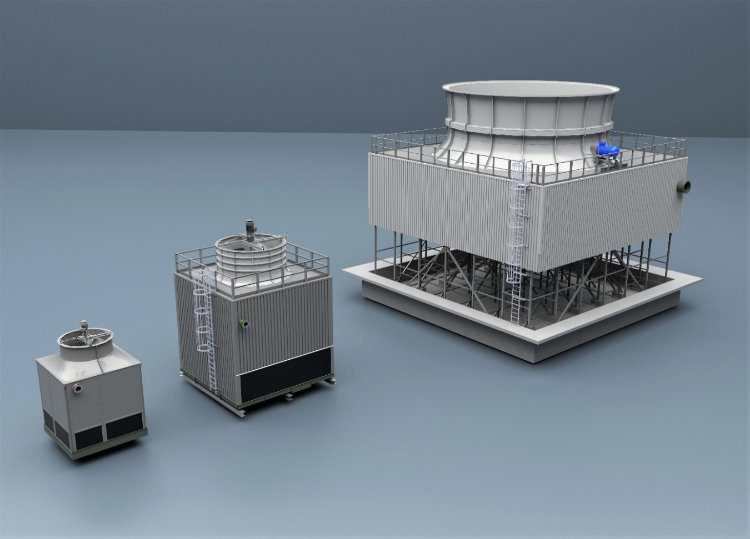

Modular open wet cooling towers of type MF, MS & KKT (counterflow-principle)

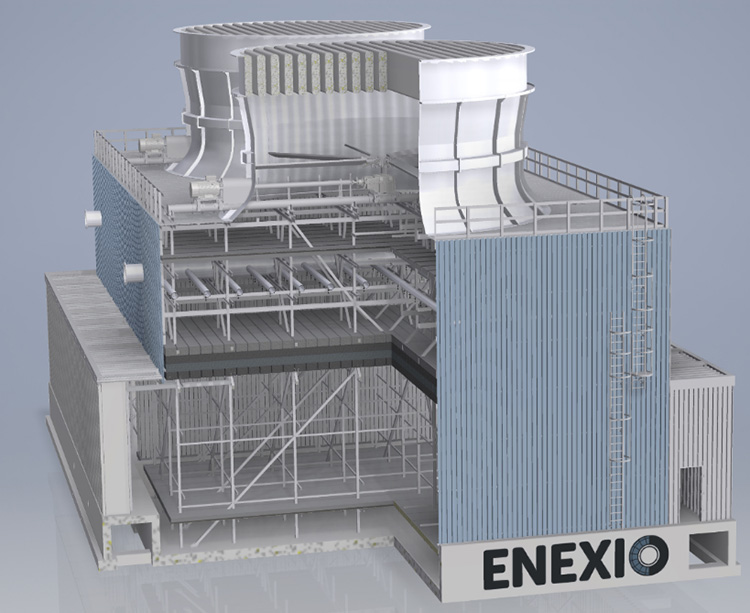

Almost any operating case can be represented by any combination of single cells and group set-up. ENEXIO Service can offer you cell cooling towers of any capacity level with sprinklered footprints from approx. 9 m² to 370 m² per individual cell. From these, complex recooling plants of any size can be combined.

The use of cellular cooling tower systems allows a flexible design that meets process requirements and environmental conditions. Furthermore, the cell design guarantees high flexibility. For example, the cells can be individually maintained and drained as needed while the system is in operation.

Available as:

- Compact Cooling tower (KKT)

– FRP Structure - M(odular) F(iberglass)

– FRP structure - M(odular) S(teel)

– Stainless steel structure

Advantage of the cell design

Rugged design is suitable for any amount of cooling water and heat output. High efficiency components guarantee the performance.

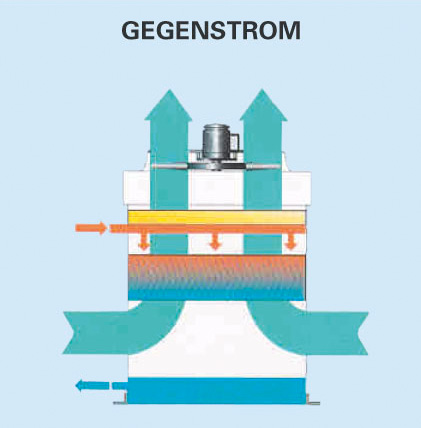

Cooling tower working scheme

Our cooling tower is (mostly) designed as a cell cooling tower. Each individual cooling tower cell operates as an evaporative cooling tower in counterflow principle. This design principle is characterized by the fact that the water to be cooled and the cooling air are fed through the cooling tower in opposite directions. Water and cooling air come into direct contact. The water is mainly cooled by evaporation of a small part of the water, and evaporation heat is extracted from the water. To a lesser extent, cooling is accomplished by convective heat transfer from the water to the cooling air. The cooling air is drawn in by a suction axial fan at the air inlet and conveyed through the cooling tower. The cooling air leaves the cooling tower cell via the air outlet of the fan as water vapor-saturated or supersaturated air. This exhaust air is referred to as a vapor. Other functional groups that are part of the cooling tower cell structure are the water distribution with the spray system, the cooling fill and the drifteliminator.

Requests

For requests please fill in our cooling questionnaire.